How Are Colored Pencils Made and the Key Ingredients Involved

Colored pencils are a beloved medium for artists, hobbyists, and students alike. Their vibrant colors and versatility make them popular for various art projects and techniques. In this article, we will delve into the fascinating world of how colored pencils are made, exploring the materials used and the intricate processes involved in their production.

A Brief History of Colored Pencils

The origins of colored pencils can be traced back to the early 19th century. As graphite pencils became more prevalent, manufacturers sought to create a similar product that offered a variety of colors. The first colored pencils were made using a mixture of pigments, graphite, and clay, which were then encased in a wooden barrel. Over time, the materials and manufacturing process evolved, and modern colored pencils now use a combination of pigments, extenders, and binding agents to create the vibrant colors we know and love today.

What are Colored Pencils Made Of?

To understand how colored pencils are made, it's important to first familiarize ourselves with the materials used in their production. The main components of colored pencils include:

- The pencil barrel

- The lead mixture

- The binder

- The pigments used for coloring

- Extenders

1. Types of Wood for the Pencil Barrel

The pencil barrel is typically made from wood, providing a comfortable grip and protecting the fragile lead inside. Two common types of wood used for colored pencil barrels are:

Cedar - Known for its straight grain and pleasant aroma, cedar is a popular choice for high-quality colored pencils. It is relatively easy to sharpen and provides a good balance of strength and flexibility.

Basswood - A lightweight, softwood with a pale color, basswood is another common choice for pencil barrels. It is less expensive than cedar and is often used for more affordable colored pencils.

2. Graphite and Clay for the Pencil Lead

Although modern colored pencils no longer contain graphite in their lead, some manufacturers still use clay as a base material. The clay helps to bind the pigments and other components of the lead together.

3. Wax, Oil, or Other Binding Agents

Binding agents are crucial for holding the pigments and extenders together, creating a smooth and consistent lead. The two most common binding agents used in colored pencils are:

Wax-based binders - These provide a smooth application and are easy to layer and blend. However, they can be prone to wax bloom, a white film that forms on the surface of the artwork over time.

Oil-based binders - Oil-based colored pencils have a harder lead, which makes them more resistant to breaking. They are also less prone to wax bloom but may require more effort to blend and layer.

Water-soluble binders: In the case of watercolor pencils, a water-soluble binder, such as gum arabic, is used to hold the pigments and other components together. This allows the pigment to dissolve in water, creating a watercolor-like effect when water is applied to the artwork.

4. Pigments for Color

Pigments are responsible for the color in a colored pencil's lead. These can be derived from natural sources, such as minerals, or they can be synthetically produced. Pigments come in a wide range of colors and have varying degrees of lightfastness, which is a measure of how resistant they are to fading when exposed to light.

5. Extenders

Extenders, such as kaolin, talc, or chalk, are used to bulk up the lead and make it easier to work with. They can also help to improve the pencil's opacity and lightfastness. However, the use of extenders can sometimes result in a less vibrant or slightly grainy color.

How Are Colored Pencils Produced?

The production of colored pencils involves several steps, from cutting and shaping the wood to creating the lead mixture and assembling the final product. Let's explore each of these steps in detail.

1. Cutting and Shaping the Wood into Pencil Barrels

The first step in making colored pencils is to prepare the wooden barrels. The chosen wood is cut into thin slats, which are then carefully shaped into a semi-hexagonal or round profile. This process requires precision and attention to detail, as the wooden slats must be uniform in size and shape.

2. Creating the Lead Mixture

The next step is to create the lead mixture. This involves combining pigments, extenders, and binding agents in precise proportions. The mixture is then heated until it reaches a semi-liquid state, allowing for thorough mixing and ensuring a consistent texture throughout the lead.

3. Extruding the Lead Mixture

Once the lead mixture is prepared, it is extruded through a machine that shapes it into long, thin strands. These strands are then cooled and cut to the appropriate length for the pencil barrels.

4. Applying the Lead Mixture to the Pencil Barrel

A groove is cut into one of the wooden slats to assemble the pencil, and the lead is carefully placed inside. Another wooden slat is glued on top, sandwiching the lead between the two pieces of wood. This creates a strong bond and ensures that the lead is well-protected within the pencil barrel.

5. Drying, Sanding, and Polishing the Pencil

The assembled pencils are left to dry, allowing the glue to set and ensuring a strong bond between the wood and the lead. Once dry, the pencils are sanded to create a smooth surface and remove any excess glue. The final step is to polish the pencils, giving them a sleek and professional appearance.

Quality Control

Quality control is essential in the production of colored pencils, as it ensures that each pencil meets the desired standards of performance and appearance. Manufacturers employ various methods and testing procedures to maintain consistent quality across batches.

1. Testing for Lead Strength and Color Accuracy

To ensure that the lead in each pencil is strong and resistant to breakage, manufacturers conduct tests on the lead mixture and the final product. These tests measure the lead's hardness, strength, and resistance to breaking under pressure. In addition, the color accuracy of the lead is evaluated to ensure that each pencil produces the desired hue.

2. Inspection of Finished Pencils Before Packaging

Before packaging, each pencil undergoes a visual inspection to check for any defects or inconsistencies in the wood, lead, or overall appearance. This ensures that only the highest-quality pencils make it into the final packaging.

3. Lightfastness Ratings and Testing

Lightfastness is a crucial factor in the quality of colored pencils, as it determines how resistant the colors are to fading when exposed to light. Manufacturers test their pencils' lightfastness by exposing them to various light sources and evaluating the degree of color change over time. The results of these tests are used to assign lightfastness ratings to the pencils, which can be an important consideration for artists when choosing their materials.

There are 2 standards for evaluating the lightfastness of colored pencils: ASTM D6901 and Blue Wool Standards.

ASTM D6901 is a standard test method for evaluating the degree of fading of dyed mulch, which is used as a ground cover in landscaping. The test method provides a way to classify the degree of fading of the dyed mulch using a scale of 1 to 5.

ASTM D6901

While ASTM D6901 (American Society for Testing Materials) is primarily used for evaluating the fading of dyed mulch, it is possible to use this test method to evaluate the lightfastness of colored pencils as well. Some colored pencil manufacturers, such as Caran d'Ache, have used the ASTM D6901 scale to show that their colored pencils are highly lightfast.

The test method involves exposing samples of the colored pencil to light for a specified period, and then comparing the degree of color change to the ASTM D6901 scale, which ranges from I (over 100 years of fade resistance) to V (less than 2 years of fade resistance).

| Description | Rating symbol | Rating in years |

|---|---|---|

| Very poor lightfastness | V | Less than 2 years |

| Poor lightfastness | IV | 2 - 15 years |

| Fair lightfastness | III | 15 - 20 years |

| Very good lightfastness | II | 50 - 100 years |

| Excellent lightfastness | I | More than 100 years |

Blue Wool Standards

The Blue Wool Standards provide a standardized method for testing and comparing the lightfastness of colored pencils, as well as other colored materials. In this testing process, samples of the colored pencil are exposed to a controlled light source for a set period and then compared to the Blue Wool Standards to determine the level of lightfastness of the colors. Fugitive colors are less fade-resistant than colors with excellent lightfastness.

| Description | Number (1 - 8) | Lightfastness rating |

|---|---|---|

| Very poor | 1 | Fugitive |

| Poor | 2 - 3 | Fugitive |

| Fair | 4 - 5 | Impermanent |

| Very good | 6 | |

| Excellent | 7 - 8 | Excellent lightfastness |

Different Types of Colored Pencils

While the basic composition of colored pencils remains consistent across various types, there are some key differences in the specific formulations and applications. In this section, we will discuss three popular types of colored pencils: watercolor pencils, oil-based pencils, and pastel pencils.

1. Oil-Based Colored Pencils

As mentioned earlier, oil-based colored pencils use an oil binder instead of wax. This gives the lead a harder texture and makes it more resistant to breaking. The oil binder also provides a smoother application and allows for more precise details in artwork. However, oil-based pencils may require more effort to blend and layer compared to their wax-based counterparts.

2. Wax-Based Colored Pencils

Wax-based colored pencils are the most common type of colored pencils and use a wax binder to hold the pigment and other components together. This binder gives the lead a smooth texture and allows for easy blending and layering. However, wax-based pencils can be prone to wax bloom, a white film that forms on the surface of the artwork over time. Wax-based pencils are ideal for artists who prefer a smoother application and the ability to blend colors easily.

3. Watercolor Pencils

Watercolor pencils have a unique lead formulation that allows them to be used both dry and with water. When used dry, they behave similarly to traditional colored pencils. However, when water is applied to the artwork, the pigment dissolves, creating a watercolor-like effect. This versatility makes watercolor pencils an excellent choice for artists who enjoy experimenting with different techniques and blending options.

4. Pastel Pencils

Pastel pencils contain a higher concentration of pigment and less binder, resulting in a softer and more powdery texture. This allows for a greater color payoff and a unique, velvety finish on the artwork. However, pastel pencils are also more fragile and prone to breakage. They are ideal for artists who prefer a softer, more blendable medium and are willing to take extra care when handling and storing their pencils.

5. Erasable Colored Pencils

The core of erasable colored pencils is made with more extenders, often chalk, to make the pigment less attached to the paper. This makes it easier to erase. These pencils are particularly useful for artists who need to make corrections or adjustments to their work, as well as for students who may require erasable options for projects or assignments. However, the erasable nature of these pencils can sometimes result in less vibrant colors and a harder lead compared to non-erasable colored pencils.

6. Metallic Colored Pencils

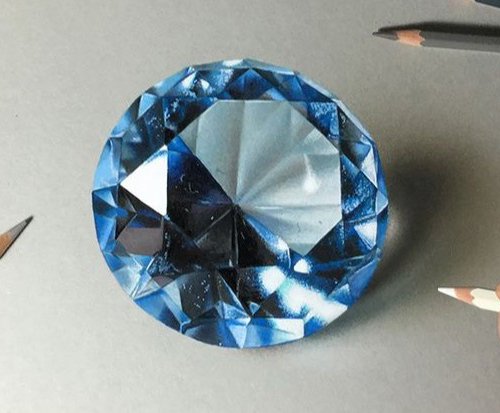

Metallic colored pencils contain pigments that give the artwork a unique, shimmering effect. These pencils are typically formulated with mica or other reflective particles, which create a metallic sheen when applied to the paper. Metallic colored pencils can be used to add dimension and visual interest to artwork and are often combined with other types of colored pencils to achieve a variety of effects.

7. Woodless Colored Pencils

Woodless colored pencils, as the name suggests, do not have a wooden barrel. Instead, they are made entirely of the lead mixture, often encased in a thin layer of lacquer or plastic to prevent the lead from breaking and to provide a comfortable grip. Woodless colored pencils offer several advantages, including the ability to use the entire pencil without waste, a larger lead diameter for broader strokes, and a slightly different feel in terms of weight and balance compared to traditional wooden-barreled colored pencils. However, they may require a bit more care when handling, as the lead is more exposed and susceptible to breakage.

Packaging and Distribution

Once the colored pencils have been produced and passed quality control checks, they are ready for packaging and distribution. In this section, we will discuss the different packaging options and the methods used to get colored pencils to stores and customers.

Packaging Options for Colored Pencils

Colored pencils can be packaged in various ways, depending on the target audience and the specific product line. Some common packaging options include:

Sets - Colored pencils are often sold in sets, which can range from small, basic collections to extensive assortments of colors. These sets are typically packaged in cardboard or metal tins, providing protection and organization for the pencils.

Individual Pencils - For artists who prefer to choose specific colors or replace individual pencils, some manufacturers also offer single pencils for sale. These are usually displayed in open trays or racks at art supply stores, allowing customers to select the colors they need.

Shipping and Distribution Methods

To get colored pencils from the manufacturer to stores and customers, a variety of shipping and distribution methods are employed. These can include:

Wholesale Distribution - Manufacturers often work with wholesale distributors who purchase large quantities of colored pencils and then sell them to retailers. This allows manufacturers to focus on production while the distributor handles the logistics of getting the product to stores.

Direct-to-Consumer - Some manufacturers also sell their colored pencils directly to consumers through online stores or catalogs. This allows customers to purchase products directly from the source, often at a lower cost than through a traditional retailer.

Retail Partnerships - In some cases, manufacturers may form partnerships with specific retailers to exclusively sell their products. This can help both the manufacturer and retailer build brand recognition and customer loyalty.

Regardless of the specific methods used, the goal is to ensure that colored pencils are efficiently and effectively distributed, making them readily available to artists, students, and hobbyists around the world.

Be the first to comment!

Comments

There are no comments yet.